Pressure Sensitive Adhesives: Product Assembly

Premier adhesive solutions for unique product assembly applications

Understanding the importance of deep substrate knowledge

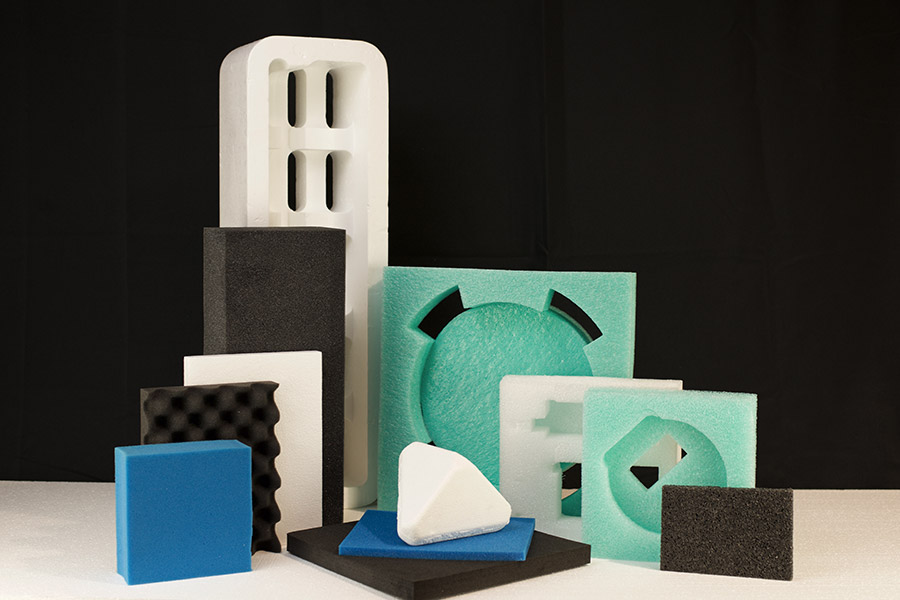

Product assembly applications can involve a wide range of substrates including: plastics, metals, wood, fabric, paper, corrugated and more. GDI Adhesives promotes a higher level of substrate understanding with our simple four step process:

- Customer collaboration

- Application understanding

- Solution design

- Customer satisfaction

Pressure Sensitive Adhesives:

Ideal for product assembly

There are many distinct advantages for using pressure sensitive adhesives (vs. other adhesive options) for in product assembly applications, including:

Open time flexibility

Adhesion strength

Low density (less weight)

Versatile cure times

Non-flammability

Low odor/VOC exposure

Moisture resistance

Knowing our past improves your future

Our GDI Adhesives chemists and technicians have compiled an encyclopedia of successful past industry applications. This experience puts GDI ahead of our competitors in being able to interpret — and quickly solve — demanding product assembly applications.

Calculated risk-tasking achieves superior results.

GDI Labs™, our team of proven adhesive experts, routinely takes on challenging product assembly applications focused on principles promoting calculated risk-taking. This means our team is not the least adverse to blueprinting challenging new customer projects from start to finish utilizing past case studies as reference. This bold yet strategic approach gives GDI the ability — and freedom — to achieve future success with proven solutions from our past.

PSAs: The modern solution for product assembly

Pressure sensitive adhesives are the preferred solution for solving advanced product assembly challenges in today’s complex manufacturing ecosystem. With a proven legacy for pioneering our customers modern production efficiencies, GDI Adhesives is the premier adhesive partner committed to fully mastering our customers product assembly world.

Glue Dots makes a critical bond with In-Sink-Erator®.

The Problem:

Essential components couldn’t be held in place.

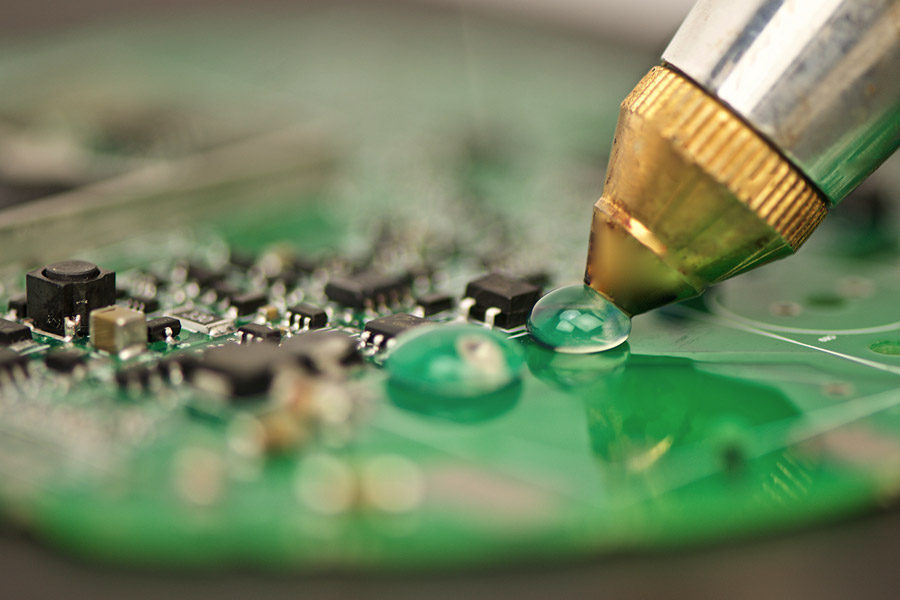

In-Sink-Erator®, the leading manufacturer of kitchen waste disposals, was to launch their new flagship product. Unlike any other model, this state-of-the-art disposal featured electronic controls, which included circuit boards and overload switches.

They discovered an unforeseen assembly problem: The circuit board and switch were positioned in a plastic housing, which workers had to turn upside-down to install the electronics. Unfortunately, the switch would not stay in place when workers turned the housing over to affix it to the unit and they had no way of keeping it in.

The Solution:

Glue Dots had a solution that stuck.

Working with the engineers at In-Sink-Erator, the experts at GDI decided to use an created a custom sized and strength adhesive that kept the switch in place during assembly. Plus, as part of the solution, the Glue Dots’ Auto Dot® Pro applicator was essential in increasing worker productivity. Workers simply positioned the switch in question onto the Auto Dot Pro, which automatically dispensed adhesive. That enabled the switch to be reliably put in place without falling out.

The Result:

One small switch enabled so much more.

With the help of the complete GDI adhesive solution:

- In-Sink-Erator avoided a costly redesign, which would have delayed the product launch

- safety, productivity and product quality were all increased

- Workers were able to assemble the switch quickly without using their fingers to hold it in place, avoiding injury and damage to the electronics.

Who will save your soles? Glue Dots.

ProFoot™, a leading manufacturer of insoles, arch supports and other footcare products, needed a versatile, simple way for customers to adhere insoles in their shoes. Glue Dots International worked closely with Valley Industrial Products and ProFoot to create a custom solution that worked for their entire product line.

The Problem:

Double sided tapes annoyed customers.

For arch supports and insoles to work properly, correct customer installation is crucial. To keep their products from slipping inside customers’ shoes, ProFoot, a leading manufacturer of insoles, arch supports and other footcare products, included double-sided tape. They offer a variety of products, each made from different materials, so a different type of tape had to be offered with each product. Unfortunately, ProFoot received numerous complaints from their customers about the performance of the tapes, the difficulty handling the tapes and frequency of insoles slipping inside the shoes.

The Solution:

One adhesive to glue them all.

Glue Dots designed a custom solution, developing one adhesive that was effective with ProFoot’s entire product line. Glue Dots tinted the adhesive blue and packaged them in two-dot sheets with a clear liner on one side and printed instructions on the other. This made applying the adhesive simple to use and virtually foolproof.

The Result:

ProFoot and their customers enjoyed more pep in their step.

The customer adhesive solution from GDI:

- Allowed ProFoot to have a single adhesive solution for their complete line of footcare products.

- Made the adhesive application process much easier and more effective for customers.

- Drastically reduced customer complaints about product slippage.

- Was a more cost-effective solution than double sided tapes

“Using Glue Dots allowed us to meet two critical goals; reduce customer complaints and create a single adhesive solution for our line of products”. – Richard Feldman, Vice President, ProFoot Inc.

GDI helps catch a better solution for a fishing manufacturer.

The Problem:

Hot melt doesn’t look so hot.

While testing a new package design, this global manufacturer of fishing products suddenly found out that traditional hot melt detracted from their new package’s aesthetics. The new design was a clear PET material, which made the hot melt adhesive — and any application errors — visible to the customer, thus eroding the brand image.

The Solution:

The right look via the right technology.

To preserve the brand image, the fishing product manufacturer turned to GDI. Our team recommended a solution centered around Low Profile, High Tack Glue Dots. With it, they’d benefit from a clean instant bond that left no mess or residue and an clear, adhesive pattern that complimented their clear PET packaging. As part of the customized solution, the addition of a SD-900 inline automated applicator allowed easy integration into the existing production process.

The Result:

GDI’s solution was clearly superior.

Glue Dots complete adhesive solution:

- Provided the clean, seamless packaging the manufacturer had wanted all along.

- Helped them avoid the expense and delay of a package redesign

- Maintained the integrity of their brand.