Filter Assembly: Ensure the Highest Level of Functionality

Helping to ensure the highest degree of filter functionality

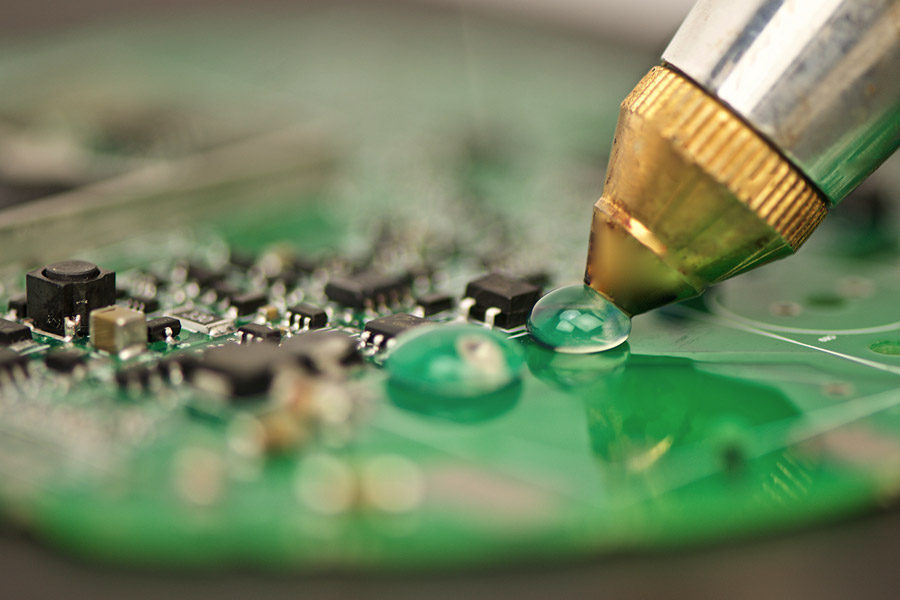

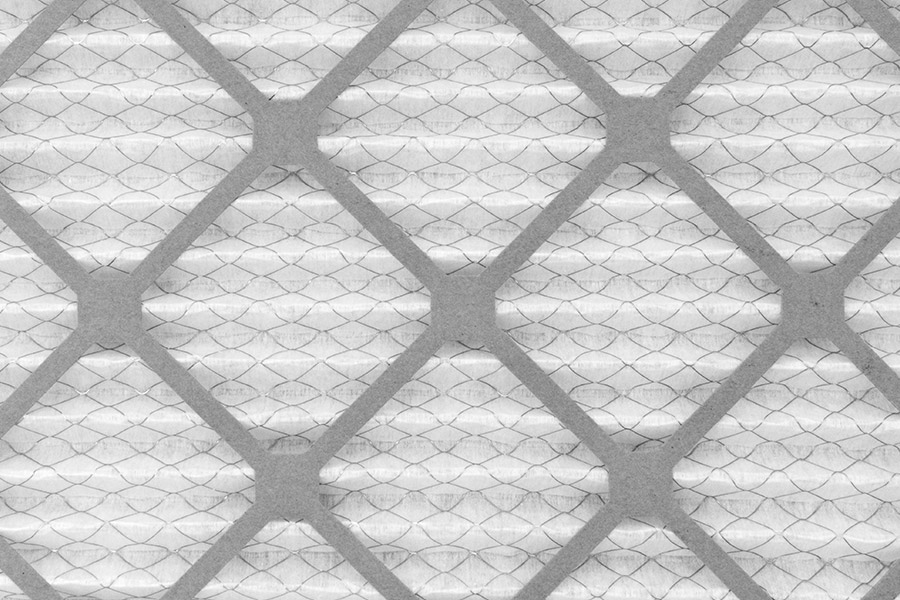

Adhesives play a complex role in the filter assembly process. From HVAC manufacturing to oil filter manufacturing, filter manufacturers rely on GDI Adhesives to tackle the intricate process of laminating multi-media substrates in the effort of realizing the highest degree of filter functionality. Our long-standing partnerships with filter manufacturing companies has enabled us to discover and solve their historical production pain points.

When it comes to filters, nothing gets past us.

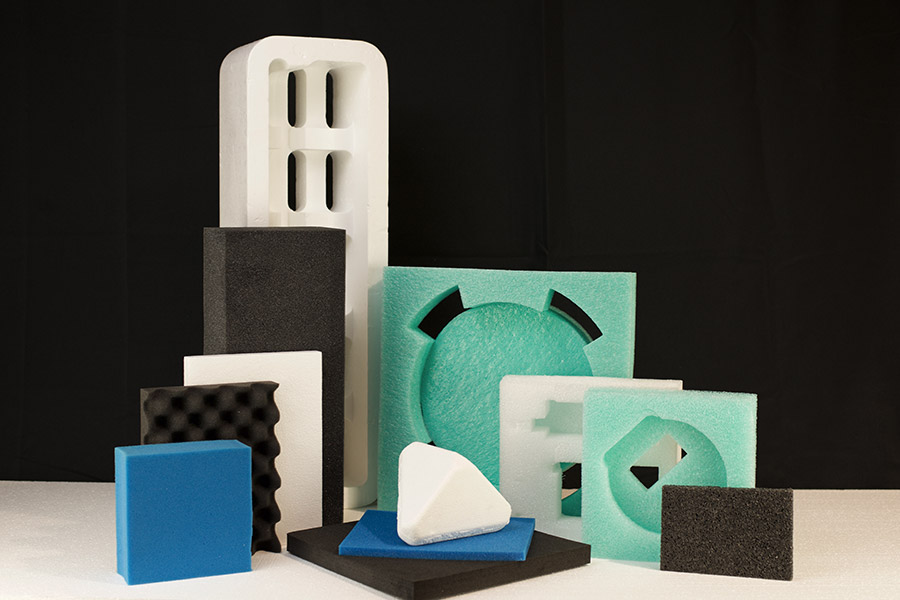

Filters come in many shapes and sizes. They filter out dust, fiber, metal, and particulate among others. These applications call for unique specifications, requiring proper adhesive matching. Frame potting, pleat stabilization, filter end capping and edge banding are a few of the many filter manufacturing applications our experts at GDI Labs™ routinely solve for.

Better efficiency through superior collaboration

From fire retardant to polyolefin and polyamide formulas, GDI Adhesives collaborates with our customers on an focused, immersive level to create the unique solutions they are searching for.

Examples of filter production applications:

Frame potting and assembly

Layer separating and stabilization

Media bonding

Edge seal pleating and banding

Potting

Gasketing

Filter end cap bonding

Some of our top tiered filter adhesive solutions:

Polyesters

Polyamides

APAOs

Polyolefins

EVAs

Hotmelts

Water-based adhesives