Packing Adhesive Solutions: Keep Brands Looking their Best

Maximize brand impact without sacrificing performance or production efficiencies.

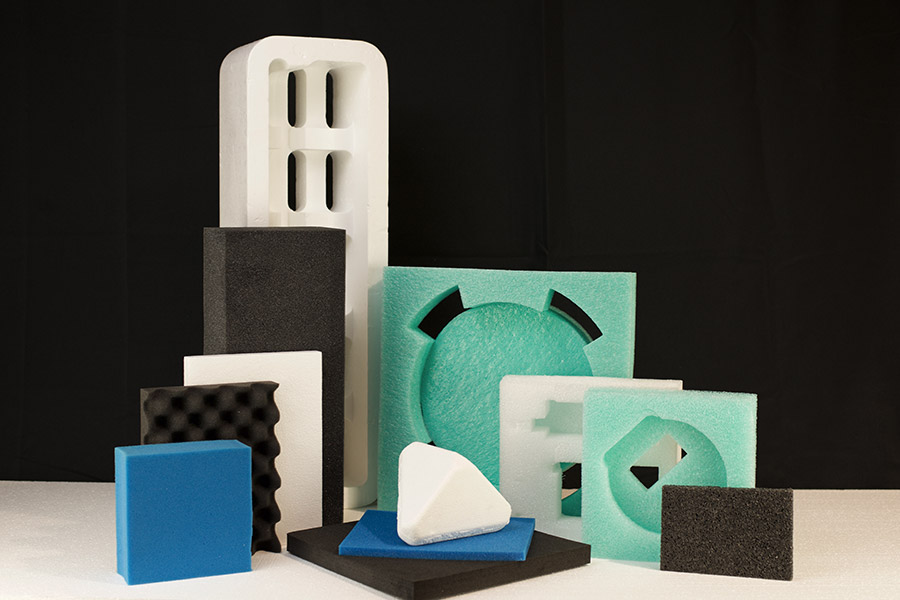

GDI adhesives are used in a wide variety of industries but the most popular applications are in the general packaging industry. Our adhesive solutions are used every day to keep brands looking their best including ensuring that product labels facing forward, holding promotional items securely in place and affixing multi-packs prior to shrink wrapping.

Glue Dots: A smart solution to nearly any packaging need

Glue Dots are designed to eliminate some of the most frustrating – and costly — packaging issues, including:

- Eliminating the danger of hot melts,

- Bypassing the mess of liquid glues

- Eliminating sticky residue left behind by inferior tape solutions

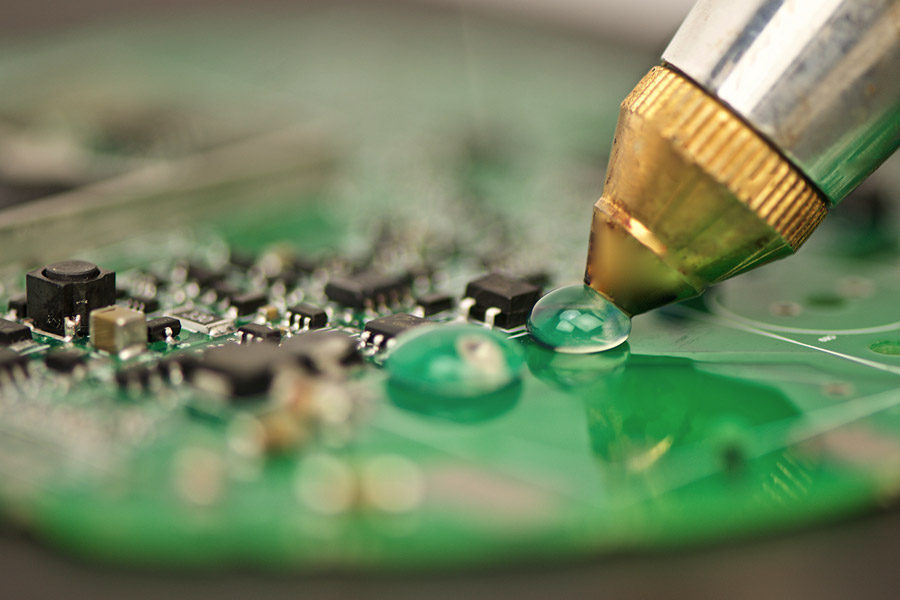

Hot Melt and Water-based Adhesives: Simply the best in the market

GDI is a recognized global leader in hot melt and water based adhesive. As a technological innovator among packaging adhesive manufacturers and suppliers, our superior package adhesive solutions are trusted in packaging for a myriad of industries around the world.

Our Hot Melt and Water-based Adhesives are commonly used for:

The FDA considers all food-contact items to be within its regulatory domain.

The food and beverage packaging industry is constantly evolving with an eye toward shifting consumer interests. Currently, suppliers are contending with a growing demand for more sustainable and convenient packaging, driving them to rethink long-held assumptions about package design.

In our informative guide, we help you learn about FDA compliant food and beverage packaging adhesives.

Glue Dots helped Unilever achieve a cleaner look.

The Problem:

How to maintain superior brand hygiene via packaging

Unilever is a world leader for consumer hygiene, nutrition and personal care products. One of those brands is the ubiquitous Q-tips® cotton swab. To promote their Q-tips Travel Kit, Unilever planned to attach it to the family-size package. The travel kits needed to be bonded to Q-Tip boxes in a clean, seamless way to reflect the brand’s hygienic attributes. Unilever initially explored the use of double-sided tape, but quickly discovered that this type of adhesive didn’t meet its standards for efficiency and cost-effectiveness. Plus, double sided tape can be messy, a huge no-no for an offering that must maintain a clean and presentable appearance.

The Solution:

Glue Dots provide the clean, removable bond for packaging

After a dedicated search, Unilever determined that Glue Dots provided the right mix of cleanliness, affordability and ease of use it was hoping to find. With the help of the GDI team of experts, a range of Glue Dots were chosen as the preferred solution for this and other critical Q-Tip projects.

The Result:

Q-tips maintain brand character and productivity

The Glue Dots solution:

- Provided a bond that was virtually invisible to the consumer, reflecting the Q-Tip® brand characteristics of cleanliness and hygiene.

- Were easily applied using our convenient dispenser box

- Became the affordable solution of choice that helped increase productivity and efficiency