The Best Foam Adhesive Solutions for Your Needs

Foam: A simple substrate poses difficult challenges

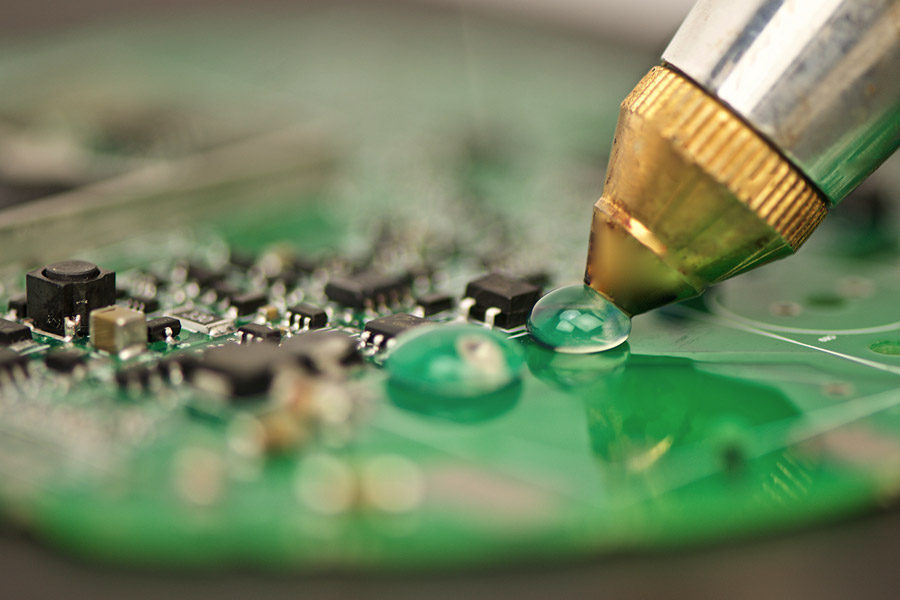

Foam is one of the most challenging substrates employed in industrial manufacturing today. Sensitive by nature due to its low surface energy, foam bonding requires a complex understanding of the relationships between substrate type, melting point and open time.

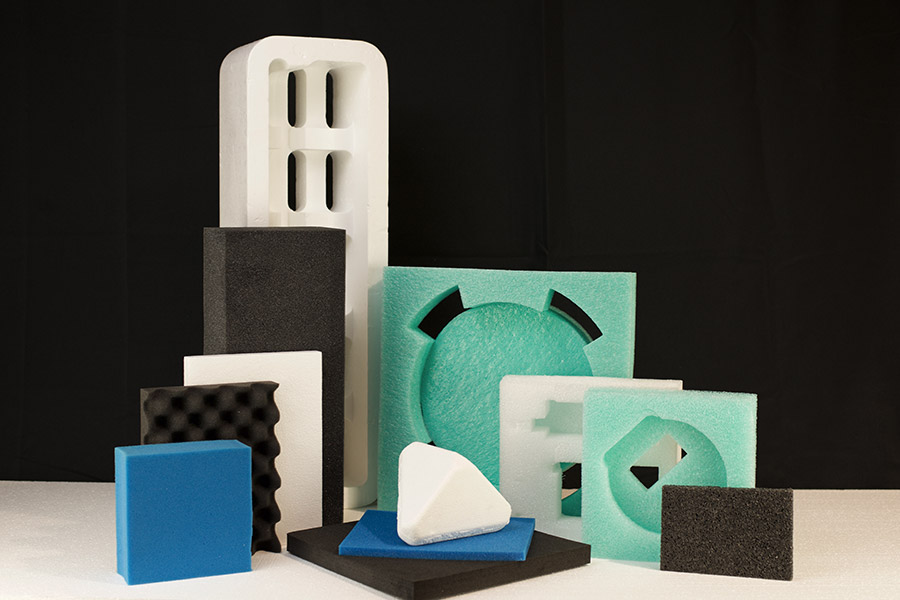

From furniture cushioning to protective packaging to acoustic paneling, foam is a foundational substrate used specifically for its unique structural integrity. Foam is found in many different materials, from polyethylene to melamine to polyurethane, not all foam applications are made equal, consequently making the process for finding the proper foam adhesive a challenging one.

GDI Adhesives makes the process of understanding which adhesive works best for your foam application as simple as possible. We possess the steadfast commitment required to achieve the best foam adhesive solution for our customers from start to finish.

The chemists at GDI Labs™ possess a diversified background of foam adhesive knowledge. This enables them to consistently create optimum adhesive solutions for our many foam assembly customers. Foam assembly also has direct ties to many of our other benchmark industries, including: Automotive, Electronic, Packaging, Furniture, Mattress, Acoustic Sound and Transportation.

Need a custom foam adhesive? No problem.

GDI Adhesives is the industry leader in providing unique, one-of-a-kind adhesive formulations tailored to foam industry applications of many types. Our solutions cover a wide range for high performance foam bond requirements reducing the needs for large inventories of narrow spectrum systems.

Examples of GDI Adhesives standard foam industry applications:

Foam-based variables solved.

From fire retardant formulas used in mattress production to high heat sensitive foams such as expanded polystyrene (EPS), GDI Adhesives knows foam assembly solutions like no other. The Formula Vault™ possesses proprietary benchmark adhesives field-proven for a large majority of foam assembly applications. Plus, The experts at GDI Labs™ are dedicated to pioneering unique adhesive solutions for the most challenging foam applications in manufacturing today.